Blockmolding machine

is designed for final expansion of EPS beads.

Preexpanded beads are fed to the blockmold and heat-treated to expand and mold themselves into a styrofoam block inside the molding chamber. Saturated water steam is used as heat transfer medium. The feeding process is automatic and pneumatically controlled through feeding valves.

The valves are actuated by a pneumatic cylinder (Camozzi, Italy). A vacuum unit is compulsory to ensure that a block is cooled and stable inside the blockmold chamber.

After cooling the block is knocked out either by the pneumatic cylinder, or by compressed air (air cushion) depending on the type of the blockmold. We manufacture two types of BLOCKMOLDS: closed and open.

The customers have an option to select the material of the inside surface: high quality carbon steel or stainless steel.The principal difference between these types of blockmolds is EPS block dimensions and capacity.

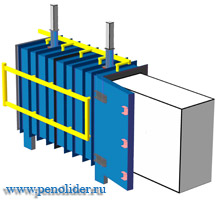

CLOSED-TYPE BLOCKMOLD

The operating chamber comprises the whole internal volume of the blockmold. The molding cycle includes the following stages:

feeding — molding — cooling — knockout

feeding — molding — cooling — knockout

As soon as the vacuuming (cooling) cycle is over, the end door opens and the finished EPS block is knocked out by compressed air onto a trolley to be transported to the sheet cutting area. The main advantage of this blockmold over the open-type one is higher capacity owing to a larger operating chamber (2,5 to 3 times as large, depending on the modification). The drawback is than the length of blocks is limited.

We can manufacture off-standard size blockmolds at the customer’s request..

Specifications

(applicable to grade 25 EPS)

|

№ |

Parameter |

BF-12 | BF-15 |

BF-16 |

BF-18 |

BF-20 |

BF-22 |

|

closed-type |

|||||||

|

1 |

Finished block dimensions(post-cut), mm., : |

1000 630 2000 |

1200 630 2000 |

1000 |

1000 |

1200 600 2700 |

1200 |

|

2 |

Capacity per cycle, cub.m |

1,26 | 1,5 |

1,6 |

1,8 |

1,95 |

21,6 |

|

3 |

Capacity per 8 hour shift, cub.m |

60-120 | 60-120 |

70-120 |

150-200 |

175-225 |

200-250 |

|

4 |

Block grade according to EN 13163:2009 |

15, 25, 35, 50 |

|||||

|

5 |

Operating steam pressure Pg inside the steam jacket of the blockmold, MPa (atm), max |

0,03 (0,3) |

|||||

|

6 |

Steam temperature inside the process chamber, °C |

104...108 |

|||||

|

7 |

Steam flow rate required for molding including preexpansion (for max capacity), kg/hour |

250* | 250* |

300* |

300* |

500* |

500* |

|

8 |

Feeding valve configuration |

pneumatic ** |

|||||

| 9

|

Knockout unit configuration |

compressed air cushion** |

|||||

|

10 |

Rated operating pressure of pneumatic cylinders, atm |

10 |

|||||

|

11 |

Serviced by, operators |

1 |

|||||

|

12 |

Dimensions, mm: width х length х height |

935 2240 2285 |

935 2240 2485 |

935 |

935 |

935 |

935 |

|

13 |

Weigth, kg |

1700 | 1900 |

2100 |

2200 |

2350 |

2500 |

|

Remarks: * Steam generating equipment has to be able to support operating pressure of 5 to 6 atm and generate at least 200-300 kg of steam per hour; **CAMOZZI (Italy) brand pneumatic cylinders. A compressor of Pg =10 atm, min. capacity 0,16 cub.m/min, receiver volume 60L is required for the normal operation of the pneumatic system. |

|||||||

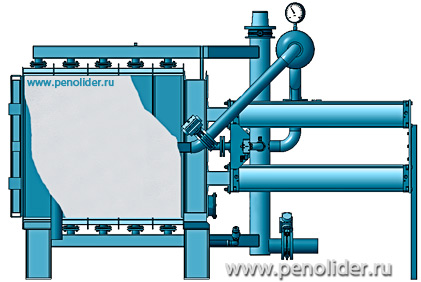

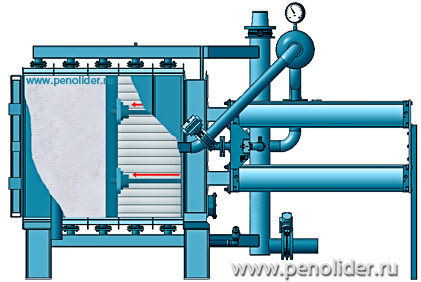

PRESS BLOCKMOLD

Our latest design (2015). The FVS 11.104 blockmold is designed for manufacture of EPS blocks from preexpanded virgin beads or from recycled (ground) beads. The blockmold supports two modes:

— regular mode: a styrofoam block is made inside the blockmold from preexpanded EPS by hot steam treatment;

— recycled mode: recycled EPS is heat-treated and compressed by means of a movable plate.

EPS block molding from virgin raw material (expandable polystyrene beads).

EPS block molding from recycled material (ground EPS).

For more information on how to produce styrofoam from recycled material click here.

Press Blockmold specification

|

Parameter |

Value |

| Process chamber | 1260×652×1038 mm, incl. adjustable to 1260 mm |

| Dimensions of a non-pressed block from virgin material |

1260…1000×652×1038 mm |

| Dimensions of a pressed block from recycled material | 800…300×652×1038 mm |

| Maximum process chamber volume |

0,853 cub.m |

| Maximum density of the finished product |

60 kg/cub.m |

| Maximum push rod speed |

2 m/min |

|

Dimensions: |

3880 mm |

|

Weight, kg |

1805 kg. |

|

Electric specifications |

|

| Supply current type |

alternating, three-phase |

| Rated current frequency |

50 Hz |

| Rated supply voltage |

380 V |

| Rated power |

4 kW |

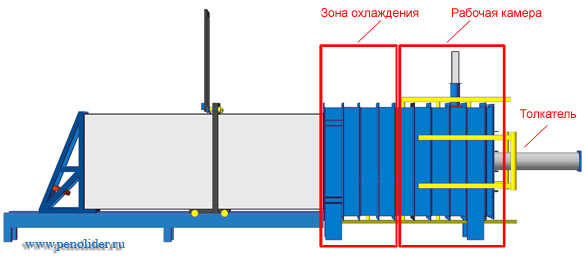

OPEN-TYPE BLOCKMOLD

The internal volume is comprised of a process chamber and a cooling compartment. A block is molded inside the process chamber and is then transferred to the cooling comparment by a push rod driven by the pneumatic cylinder. New batch of material is fed to the empty process chamber, and the molding cycle repeats.

The machine operates in a batch/continuous mode. A section of the block molded during each cycle in the process chamber is sintered onto the previously molded block inside the cooling compartment. The strength of this joint is virtually the same as the strength of the body of the block. In this way, the machine produces an endless (in theory) bulk of expanded polystyrene cut into blocks of required lengths. Standard guide length is suitable for blocks of up to 2000 mm. This length can be increased to 3000 mm at the customer’s request.

Open-type blockmold specifications

The structure of this blockmold is patented, Russian patent No 40019.

Manufacture, sale and use of open-type blockmolds produced by companies or persons other than VyatkaStroyDetal Group is a prosecutable offense.