The following types of cutting machines are used to adjust the sizes of EPS blocks:

Multi-purpose block cutting unit (Integrated cutter)

The machine is designed for horizontal and vertical cutting (crosscutting & Edge trimming). Cutting EPS blocks works automatically. It is possible to switch to manual control mode. An electronic control system for the heating of the strings is used, as well as a smooth adjustment of the speed of movement of the cutting frames. Complex cutting has high precision due to the performance of all operations from one installation without the need to transfer a block from one machine to another.

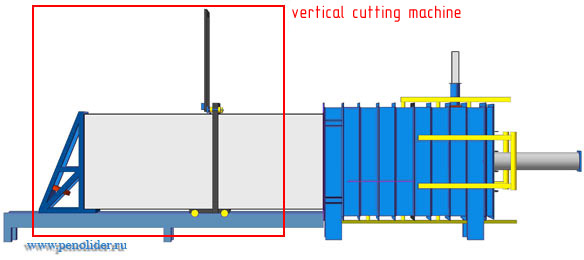

Vertical cutting machine

Vertical cutting machine is located directly behind the an UNFB blockmold and serves for cross-sectional cutting of the molded "infinite" bulk of EPS into large dimensional block of necessary length. The cutting is thermal.

The molded EPS bulk goes down the horizontal sliding rails with a cutting frame moving along. The end stop functions there as the end wall of the blockmold and does not allow the previously molded bulk to change its position as the new molding cycle goes on. The end stop uses rollers to move along the sliding rail and can be fixed using an operating console by means of a pneumatic brake cylinder.

The cutting frame does not use any drives to perform its movement, it is effected under gravity. The cutting frame is equipped with nichrome wire which is heated by a transformer.

Horizontal sheet cutter

The machine is designed for horizontal cutting of a molded EPS block into sheets of defined thickness. The cutting is thermal.

The machine is designed for horizontal cutting of a molded EPS block into sheets of defined thickness. The cutting is thermal.

The EPS block positioned on a movable carriage goes through a cutting frame equipped with nichrome wire. The wires are heated by a transformer with a capacity of 2,5 kW.

The feed motion is effected without any drives. The carriage with an EPS block goes through the wires under gravity. This is achieved by defining a necessary inclination of the sliding rails. The inclination can be regulated depending on EPS density.

If trimming to size at the sides of a sheet is required, our company can install two additional vertical wires.

Specification

|

Parameter |

Value |

|

Maximum section of a block cut, mm |

1030 х 520 (1240 х 650)* |

| Nominal length of a block cut, mm |

2000 |

| Duration of cutting (for one block), min |

5 |

| Number of cutting cycles per hour including servicing time |

12 |

| Feed motion |

the weight of carriage and an EPS block |

| Bulk weight of blocks cut, kg/m3 |

9...40 |

| Inclination control range, deg. |

0...23 |

| Service norm, persons |

1 |

| Dimensions (width / length / height), mm |

1320 х 3600 х 1425 |

| Weight, kg |

130 |

|

Electrical facilities specification |

|

| Power lines current type |

alternating three-phase current |

| Current frequency rating, Hz |

50 |

| Power circuit rated voltage, V |

380 |

| Secondary network rated voltage, V |

26...36 |

| Number of transformers in a machine |

1 |

| Transformer rated output, kW |

2,5 |

| Note: * The data in brackets concerns the values acquired using a BF-15 blockmold | |