PV-2 Preexpanderis designed for the preexpansion of expandable polystyrene beads by means of thermal processing. Saturated steam is used there as heat-transfer agent. All preexpanders can be divided into 2 types:

The preexpander we manufacture is a BATCH TYPE preexpander. Continuous type preexpander disadvantages: 1) It is only possible to control 2 factors while expanding:

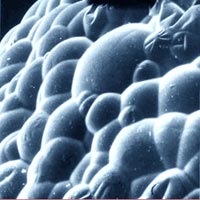

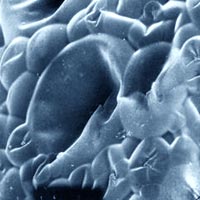

2) Steam pressure can only be decreased (by means of mixing it together with the air), but not increased, as the process is accompanied by air pressure (continuous type preexpanders are open and totally uninsulated vessels). 3) The raw material average residence time in the continuous type preexpander is abour 3 minutes, the minimum density of expanded granules directly connected with the contents of pentane in raw material. Batch type preexpander advantages: 1) Steam pressure can be regulated, that is why it is possible to adjust steam temperature to the required density or the level of pentane contents in raw material. !!! Steam temperature that does not conform to the requirements may lead to the deformation of the cells.

The lower the level of pentane in raw material, the later the expansion begins and the higher the required temperature is.

Specification (for the production of EPS density 25)

| ||||||||||||||||||||||||||||||||||||||||||

- EPS blocks and sheets manufacturing equipment

- Insulated Concrete Forms (ICF) manufacturing equipment

- Clinker Panel